5. Poynton Collieries: Progress and Decline Part 1

1857-90 Years of change and progress

With the retirement of Thomas Ashworth in 1857, the position of agent was filled internally by John Hadwen who had been manager of the underground works. Under his control the collieries saw few changes although output rose to 243,673 tons in 1859, a figure which was most likely never exceeded during the rest of their life.

The output of the collieries was tied closely to the fortunes of the cotton industry and the cotton famine caused by the American Civil War in the early 1860's had a drastic effect on coal sales. As profits fell Hadwen tried to maintain prices which led to a loss of business to other collieries in the area. In early 1863 with the fortunes of the pits at a low ebb and men laid off, John Hadwen died. Clearly a firm hand was needed to steer the collieries through this difficult period and who better than George Clementson Greenwell. He was earning £500 per annum as manager of the Radstock Collieries but had incurred Lady Waldegrave's displeasure for his interests in the development of the Westbury iron ore field and the offer of a salary of around £750 per annum was enough to bring him to Poynton as agent.

Profits were down to £3662 for the year 1862-1863 on a vend of 112,840 tons and Greenwell immediately set about increasing efficiency and reducing working charges. Prices were reduced from 8s 0d to 7s 8d per ton for coal and from 4s 1d to 3s 9½d per ton for slack but this was matched by the reduction in working expenses. Although screening had been suggested in 1856 it had not been introduced and only now were screens introduced at Park Pits with the intention of increasing the quantities of house coal to 45% or 50% from 30%. In an attempt to use the small dust coal twelve coke ovens were erected and were expected to consume 120 to 130 tons of coal per week in producing 70 tons of coke. Whilst the screens proved to be a great success and their use was extended to the other pits, the coke ovens were less so and no more were erected as the coke proved to be good only for a few uses. Coke output in 1864 was 1457 tons at a cost of 8s 4d per ton but production ceased in 1868. Output for the year 1862-63 by pit was as follows:

| Tons |

| Anson | 48,773 |

| Nelson | 18,391 |

| Park 4 Foot & 5 Foot | 64,680 |

An extra product that appears in the accounts at this time is ironstone which is found with the four foot seam. This was usually calcined at the pits before sale and in 1865, 1022 tons were calcined and 594 tons sold raw. The profits on calcined ironstone were high, a ton selling for a net average price of 11s 10¼d in 1865 whilst only costing 5s 4d per ton to mine and calcine. The last record of ironstone production is in 1874 when stone to the value of £23 15s 10d was sold.

The next aspect of the collieries to receive attention was the cost of pumping

water from the workings and very soon some disturbing facts emerged.

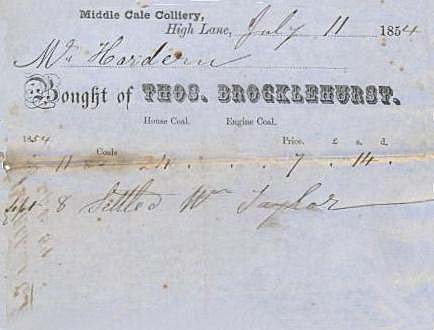

"Messrs Brocklehurst Colliery at Norbury 3

....have a Pit sunk to the Red Acre Mine which lies about 100 yards under the

Accommodation Seam, which is the lowest seam we work and to which the Canal

Pit is sunk. Messrs Brocklehurst's pumping arrangements are by means of a Steam

Engine to pump the water of the Red Acre Mine up to the Accommodation Seam whence

it runs to another pump, worked by a water wheel, which ought to lift this and

the other water to the surface at a Pit also on the Norbury Estate.....In dry

weather however there is not sufficient water in the Brook to drive the Water

wheel fast enough to pump their water. Consequently it flows through a communication

made, I am informed some time ago, by the Norbury Lessees with the Poynton workings.

They are at present raising about 500,000 gallons of water per week by their

pumping engine from the Red Acre Seam to the Accommodation Seam, but only pumping

about 175,000 gallons per week from this Seam to the surface thus allowing about

325,000 gallons per week to flow to Poynton. We are at present pumping about

500,000 gallons per week at the Canal Pit, two thirds of which I am satisfied

does not belong to us." 4

"Messrs Brocklehurst Colliery at Norbury 3

....have a Pit sunk to the Red Acre Mine which lies about 100 yards under the

Accommodation Seam, which is the lowest seam we work and to which the Canal

Pit is sunk. Messrs Brocklehurst's pumping arrangements are by means of a Steam

Engine to pump the water of the Red Acre Mine up to the Accommodation Seam whence

it runs to another pump, worked by a water wheel, which ought to lift this and

the other water to the surface at a Pit also on the Norbury Estate.....In dry

weather however there is not sufficient water in the Brook to drive the Water

wheel fast enough to pump their water. Consequently it flows through a communication

made, I am informed some time ago, by the Norbury Lessees with the Poynton workings.

They are at present raising about 500,000 gallons of water per week by their

pumping engine from the Red Acre Seam to the Accommodation Seam, but only pumping

about 175,000 gallons per week from this Seam to the surface thus allowing about

325,000 gallons per week to flow to Poynton. We are at present pumping about

500,000 gallons per week at the Canal Pit, two thirds of which I am satisfied

does not belong to us." 4

Brocklehursts did not take any action to alter this state of affairs at first and in 1865 Greenwell wrote a strong letter telling them to stop sending their water into the Poynton workings after which no more is heard of the matter.

Further water was found to be entering the pits through a fissure in the bed of the Norbury Brook and this was carefully puddled during 1864. In the 1860s control of the water problem was the key to Greenwell's plans to open out the Five Foot Coal to the deep side of the Park Pits and the Accommodation and Reform seams to the deep side of Anson Pit for which two Engine Planes were being constructed in these pits. He proposed sinking the Lady Pit to the Accommodation Seam, 50 yards lower than it was already sunk and concentrating the pumping establishment there.

Work on deepening Lady Pit commenced in May 1866 and the rest of the shaft was walled with bricks where necessary from the surface to the Gees Mine. The tunnels to take the water from Park and Anson Pits were started soon after. The level in the Accommodation mine from Anson Pit was completed in 1868 but work on the level in the Gees mine from Park Pits was stopped until the pump was installed due to striking water and the possibility of meeting more and being unable to cope with it.

Two approaches to pumping at Lady Pit were considered:-

"1) A Cornish Engine to be placed at the surface of the Lady Pit; with a cylinder 90 inches in diameter and suitable pumps to lift the whole of the mine feeders; cost £5000.

2) A double cylindered horizontal engine placed at the bottom of the pit (the steam being taken down the shaft) with suitable pumps to force the water to

the surface; cost £4000" 5

Both types of pump had certain advantages, the former being cheaper to work, easier

to adapt to deeper workings later and not liable to inundation in case of a breakdown;

the latter would be cheaper to install and would not need pump rods. The final

decision was deferred due to the depressed state of the coal trade. It was estimated

that the new arrangements would eventually save £1000 per annum in pumping

costs.

Finally in February 1871 Greenwell was able to report that a suitable engine

had been acquired. 6

"I have agreed with Messrs Harvey & Co the Eminent engineers of

Hayle Foundry, Cornwall, to erect the pumping engine at the Lady Pits as referred

to in my previous reports. The diameter of the cylinder is 80 inches: it is

second hand and the price to be paid for it, erected and set to work £1400.

The engine house is partly erected, but the work has been suspended since Christmas

by the frost." 7

The engine was finally ready for work in 1875.

|

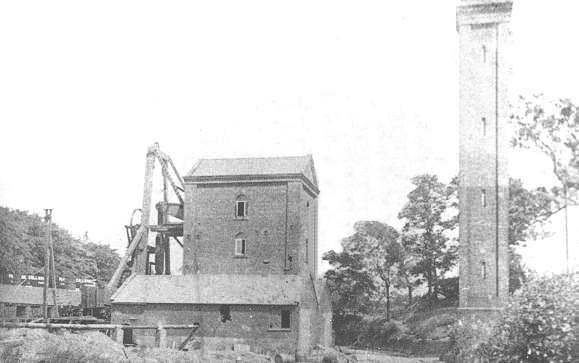

| Cornish pumping engine at Lady Pit, c1900 |

"The setting up and getting to work of this engine and pumps has been

chiefly done by our own people and as they have had their other work to

do the progress has been slow, it is now however near completion and I hope

will be shortly at work."

By 1879 this engine was working three days per week but it was not until 1883

that the waterway from Park Pits reached Lady Pit and the pumping of water to

the surface at Park was dispensed with.

The attention that Greenwell paid to introducing new ideas and cutting costs rapidly

showed in improving profits. Sales rose to 162,383 tons in 1867 yielding a profit

of £25,557 but the next year there were more problems when demand fell considerably

and consequently so did prices. Wages were reduced resulting in a strike from

17 January to 13 February when the men resumed work at the reduction, and a further

wage reduction was introduced without resistance in May. Profits fell back to

£9979 on a vend of 131,894 tons but rose over the next few years to an all

time record of £42,263 in 1873.

In 1875 Lord Vernon requested a report on the present position of the collieries and their future prospects. This was produced in February and is similar to that written in 1856. 8

The average vend for the eleven years 1864-75 was 153,193 tons yielding an

average profit of 2s 6d per ton compared with 219,700 tons per annum for a profit

of 1s 4d per ton in the years 1857-1862. Greenwell's agency had certainly improved

the profitability of the concern.

On considering the coal reserves the following table gives the position; 9

| Seams, working or partly worked | Thickness (ft. in.) | Acres Won | Acres Unwon | Tons Won | Tons Unwon |

|---|

| 10 Foot | 7.0 | 130 | | 1,092,000 | |

| 4 Foot | 3.10 | 10 | 16 | 46,000 | 73,700 |

| 5 Foot | 5.0 | 40 | 35 | 240,000 | 210,000 |

| Gees | 3.2 | 185 | 288 | 703,000 | 1,094,000 |

| Reform | 2.6 | 766 | 296 | 2,298,000 | 888,000 |

| Top Block | 2.0 | 44 | | | |

| Accommodation | 7.2 | 380 | 367 | 3,373,600 | 3,156,200 |

| | | | ____________ | ____________ |

| | | | 7,752,600 | 5,421,800 |

| Seams unworked | | | | | |

|---|

| Two Foot | 2.0 | 750 | | 1,800,000 | |

| Twenty Inch | 1.8 | 680 | | 1,360,000 | |

| Redacre | 2.2 | 163 | 1087 | 423,800 | 2,826,200 |

| | | | ____________ | ____________ |

| | | | 3,583,800 | 2,826,200 |

| | | | ____________ | ____________ |

| | | Total | 11,336,400 | 8,248,000 |

|---|

| | | | | |

Greenwell devoted a considerable amount of the report to considering these reserves and planning their long term extraction. He divided the collieries into four districts:

1) The Anson District

| Tons |

| Gees | 476,750 |

| Reform | 2,115,000 |

| Accommodation | 1,754,000 |

| ___________ |

| Total | 4,345,750 |

All this coal was won.

This district contained much inferior quality Reform Coal which was only usable in locomotive engines and was considered unlikely to be touched for some time. To work it efficiently would require coal cutting machinery which was relatively new and expensive but worth considering. The proposed quantities to be drawn were:

| Tons per annum |

|---|

| Gees | 20,000 |

| Reform | 10,000 |

| Accommodation | 70,000 |

| ___________ |

| Total | 100,000 |

This would keep the Anson Pit working for 25 years and still leave a large quantity of Reform coal plus the Redacre and other small seams.

2) The Park District

| Tons |

|---|

| Ten Foot | 882,000 |

| Four Foot | 119,600 |

| Five Foot | 450,000 |

| Gees | 199,950 |

| Reform | 166,000 |

| Accommodation | 1,619,200 |

| ____________ |

| Total | 3,436,750 |

The Ten Foot coal was recommended to be left for some years due to its tendency to being "tender and bandy" (liable to break up easily and with dirt bands in it) but the rest should yield 100,000 tons per annum made up:

| Tons per annum |

|---|

| Four and Five Foot | 20,000 |

| Gees and Reform | 14,000 |

| Accommodation | 66,000 |

| ___________ |

| Total | 100,000 |

This quantity would last for 25 years.

3) The Deep Park district; which comprised the whole of the Gees, Reform and Accommodation coals lying below the level of the bottom of the Park Oval Pit and the East of the Park Fault.

| Tons |

|---|

| Gees | 377,950 |

| Reform | 324,000 |

| Accommodation | 1,393,000 |

| ___________ |

| Total | 2,094,950 |

This would be reached by deepening the Park Pits to 320 yards.

4) The Vernon District; comprising all the unworked coal in the Ten Foot, Gees, Reform and Accommodation seams lying between the Park, the Red Rock and the Worth Hall Faults.

| Tons |

|---|

| Ten Foot | 210,000 |

| Gees | 742,750 |

| Reform | 581,000 |

| Accommodation | 1,763,000 |

| ___________ |

| Total | 3,296,750 |

This coal would be worked by a pit to be sunk at or near the Lower Vernon Pit to the Accommodation Seam at a depth of about 320 yards. Districts 3 and 4 were to supply 200,000 tons of coal per year for 26 years after the closure of the Anson and Park districts leaving after 51 years a total of 9,117,000 tons of coal.

A large new pit would be required at Lower Vernon Pit plus much work at Park Pits in order to carry out this plan. In addition a new winding engine was urgently needed at Park Oval Pit in order to draw 100,000 tons per annum there and the railways were to be modernised and improved to allow locomotive haulage. The purchase of a new winding engine for Park Oval Pit was immediately put in hand and a fine two cylinder engine was erected during the year. It must have greatly improved the capacity of the Oval Pit and replaced the old Albert Pit Engine which had been drawing coals there since 1857.

Obviously the future of the Collieries had been well planned by Greenwell to yield 200,000 tons a year for well over half a century but this was not to be. For economic reasons a market could not be found every year for such an output and the colliery plant and railway system were inadequate for such demands until 1890. In 1877, Greenwell retired and handed over the reins to his son G.C. Greenwell junior who was to act as agent until 1919. The vend in 1877 was 143,005 tons for a profit of £12,884. This was from Park and Anson Pits. The Nelson and Canal Pits were closed during the 1870s.

During 1879 he was trying to sell coke again. "Coke Ovens at Park Pit ...... We have had two of these ovens put in repair and have tried both Anson and Park coal in them" 10

The experiment was obviously unsuccessful as coke production is not mentioned again. Slack from Park Pit was also causing problems as it needed washing to make it saleable. A washing plant was considered but again nothing seems to have come of the idea.

It is interesting to note that coal drawing was started at Canal Pit soon after Greenwell Senior retired, an action which certainly did not accord with the policy of concentrating production at the largest, most economical pits. In 1879 Canal Pit produced 7691 tons which cost 5s 8¾d per ton to produce whereas the average cost of production for coal at the Poynton Coal Yard was only 4s 35⁄8d per ton. Production at Canal Pit continued on and off until 1888 when only 1543 tons were raised.

A far more practical development undertaken by the new agent was the improvement of the ventilation for Anson Pit in 1882.

"Horse Pasture Pit. The engine and boiler which stood at the German

Pit have been removed and erected at this Pit. It has been cleaned out and sunk

to within a few yards of the Gees Mine and a Borehole has been put down to take

the water into the Gees Mine from which it runs past the Anson Pit to the Lady

Pit ...... It is proposed to complete the sinking to the Gees Mine as soon as

arrangements can be made and to utilise this pit as an upcast for Ventilating

the Anson District." 11 A ventilating

furnace was erected in this pit and continued to provide the main ventilation

for the Anson pit until it closed.

Output was still only 135,797 tons in 1883 for a profit of £3411 and

the plans of 1875 were not coming to fruition. It was obvious that the majority

of the reserves were in the Accommodation seams lying in the Park District and

to the deep side of the Park and Vernon Pits. The other seams would provide

coal for a number of years but in order to increase output to 200,000 tons or

more per year a new sinking was becoming increasingly necessary.

| |

|

|

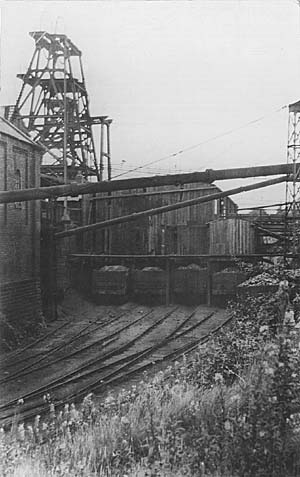

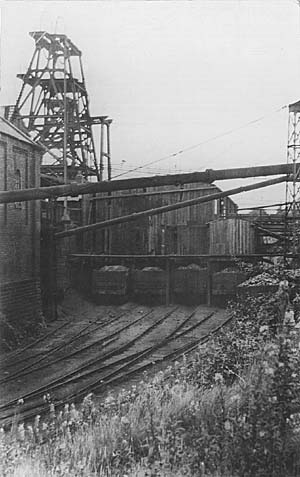

Screens, Park Pits. The large pipe carried exhaust steam

from the Lawrance winder to

the turbine. c1930

|

The original plan to sink a new Vernon Pit and to deepen the Park Pits was

modified probably because of the cost. It was decided instead to sink a new

shaft at the Park Pits down to the Accommodation Mine and to deepen the Round

Pit to the same seam to act as upcast (shaft up which the foul air was drawn)

for the new mining. This plan had the advantage of concentrating new production

at Park Pits where surface handling arrangements already existed, but did result

in rather cramped conditions at the pit head. Estimated cost was £12,000

and work commenced in early 1884. The first progress report was in March 1885.

"During the year preparations have been made at the Round Pit for sinking

and this pit hasbeen deepened from 160 yards to 220 yards or by 60 yards. New

Shops and Offices have been built. A Pumping Engine has been fixed at the Ten

Foot Seam in the Round Pit, a depth of 60 yards from the surface, to pump the

Ten Foot water which in wet weather becomes a considerable quantity and which

if not pumped at this Pit would have to fall 140 yards to the level at which

the main feeder runs away to the Lady Pit ...... A new Headgear has been made

for the Oval Pit and preparations have been made for alterations in the arrangements

at the Oval Pit and for commencing the New Pit which it is proposed to sink

at a point about 10 yards to the South of the Oval Pit to the Accommodation

Seam. Between the end of the year and now (March 85) these preparations have

been completed and the sinking of the New Pit will be commenced at once - with

good luck we should I think complete the sinking in about 12 months and should

be able to open out some coal by the Winter of 1886." 12

It was becoming very urgent to complete the new pit as the Accommodation Seam

at the Anson Pit was not going to last for the 25 years that Greenwell had predicted

and the workings were rapidly becoming exhausted. Difficulties were also being

experienced in opening out the Gees seam at this pit and coupled with reduced

output at Park Oval due to the new works the vend for 1884 fell to only 123,340

tons.

During 1885 the new winning was named Lawrance Pit after the maiden name of

Lord Vernon's new bride, Miss Fanny Lawrance. The shaft was 13 feet in diameter

and was lined throughout with 9 inch special bricks set in mortar. It reached

the Accommodation seam at 312 yards in 1886. A new steel headgear was erected

and two deck cages to take four tubs each were installed. Extra screening plant

and a further siding were also built in order to cope with the increased output.

The final cost was £19,000 made up as follows:

| Lawrance Pit winning and necessary plant in connection therewith | £16,405 5s 10d |

| Pumping apparatus at Park Round Pit to relieve pumping at Lady pit | £386 4s 6d |

| Brass lined working barrels for Lady pit pumps | £445 0s 0d |

| 25 New Railway Wagons | £1,095 0s 0d |

| Alterations top and bottom Park Oval Pit | £688 9s 8d |

The first coal was raised from the new pit in 1886, the output for that year

being 2165 tons. This was the last pit to be sunk at Poynton and the resulting

improvement in output and profitability was summed up in early 1890 by G.C.

Greenwell junior.

"The Lawrance Pit is fairly opened out and we are now altogether working at the rate of nearly 240,000 tons per annum, which quantity should I think not be exceeded If we can only keep dear of accidents and disputes with the workmen I think a time of prosperity for Poynton Collieries may fairly be calculated upon." 13

Profits for 1890 reached £31,003 for a vend of 216,362 tons. The collieries

were entering the last period of their history on a high note, the investment

in a new pit had been entirely justified with one year's profits easily covering

the outlay.

| |

|

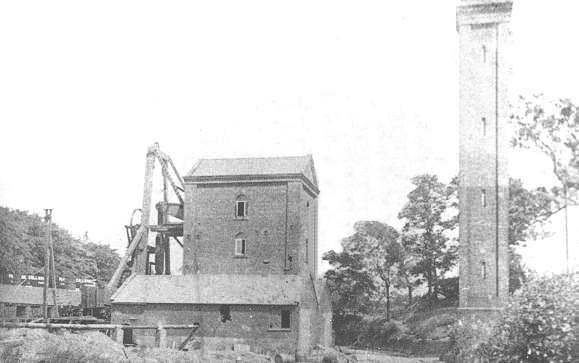

| Park Pits, 1926. Shafts left to right: Lawrance, Oval,

Round. Powerhouse on left |

For further information see:

Poynton A Coalmining Village; social history, transport and industry 1700 -

1939, by W.H.Shercliff, D.A.Kitching and J.M.Ryan, published by W.H.Shercliff,

1983. ISBN 0 9508761 0 0

Poynton Collieries: 1832-57 Development under

the Vernons

Poynton Collieries: 1857-90 Years of change and

progress Part 2

Poynton Collieries Index

© David Kitching 2014

Last updated 7.6.14

"Messrs Brocklehurst Colliery at Norbury 3

....have a Pit sunk to the Red Acre Mine which lies about 100 yards under the

Accommodation Seam, which is the lowest seam we work and to which the Canal

Pit is sunk. Messrs Brocklehurst's pumping arrangements are by means of a Steam

Engine to pump the water of the Red Acre Mine up to the Accommodation Seam whence

it runs to another pump, worked by a water wheel, which ought to lift this and

the other water to the surface at a Pit also on the Norbury Estate.....In dry

weather however there is not sufficient water in the Brook to drive the Water

wheel fast enough to pump their water. Consequently it flows through a communication

made, I am informed some time ago, by the Norbury Lessees with the Poynton workings.

They are at present raising about 500,000 gallons of water per week by their

pumping engine from the Red Acre Seam to the Accommodation Seam, but only pumping

about 175,000 gallons per week from this Seam to the surface thus allowing about

325,000 gallons per week to flow to Poynton. We are at present pumping about

500,000 gallons per week at the Canal Pit, two thirds of which I am satisfied

does not belong to us." 4

"Messrs Brocklehurst Colliery at Norbury 3

....have a Pit sunk to the Red Acre Mine which lies about 100 yards under the

Accommodation Seam, which is the lowest seam we work and to which the Canal

Pit is sunk. Messrs Brocklehurst's pumping arrangements are by means of a Steam

Engine to pump the water of the Red Acre Mine up to the Accommodation Seam whence

it runs to another pump, worked by a water wheel, which ought to lift this and

the other water to the surface at a Pit also on the Norbury Estate.....In dry

weather however there is not sufficient water in the Brook to drive the Water

wheel fast enough to pump their water. Consequently it flows through a communication

made, I am informed some time ago, by the Norbury Lessees with the Poynton workings.

They are at present raising about 500,000 gallons of water per week by their

pumping engine from the Red Acre Seam to the Accommodation Seam, but only pumping

about 175,000 gallons per week from this Seam to the surface thus allowing about

325,000 gallons per week to flow to Poynton. We are at present pumping about

500,000 gallons per week at the Canal Pit, two thirds of which I am satisfied

does not belong to us." 4