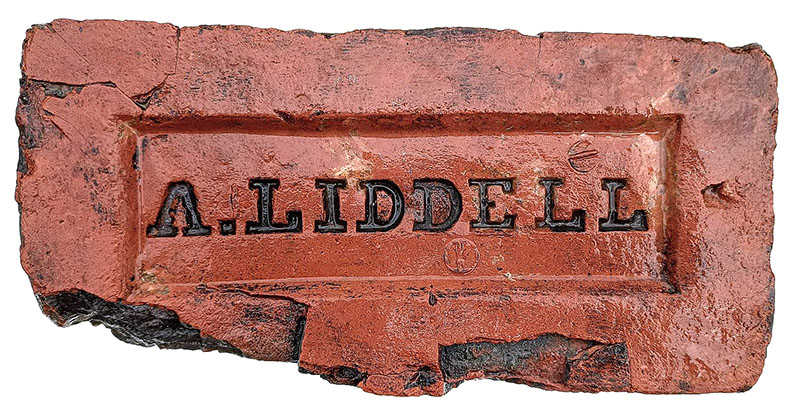

Aaron Liddell of Shincliffe Brick Works was charged with refusing to pay a Poor Rate - Durham County Advertiser - 15 March 1867. Partnership of Aaron Liddell, Mr Lowe (butcher of Shincliffe) and Mr Sanderson (builder of Durham) at Shincliffe Brick & Tile Works ordered to be dissolved, partnership property sold and receiver to be appointed due to the inappropriate behaviour of Liddell - Durham County Advertiser - 19 February 1869. Photo by Chris Tilney.

The Lilleshall Company opened its mechanized Donnington Wood Brickworks on Pain's Lane, Lilleshall in 1876. By 1908 it was producing 3 to 4 million high quality bricks per year, but after the 2nd World War production declined due to expense & the works closed in 1972. Info by Martyn Fretwell.

Photos by Phil Burgoyne.

Oliver Richardson spotted this one in Shropshire.

Found on an allotment in Shrewsbury by Mike Shaw.

.jpg)

Found at North Shropshire Recycling yard by Martyn Fretwell.

Photo by Jason Stott.

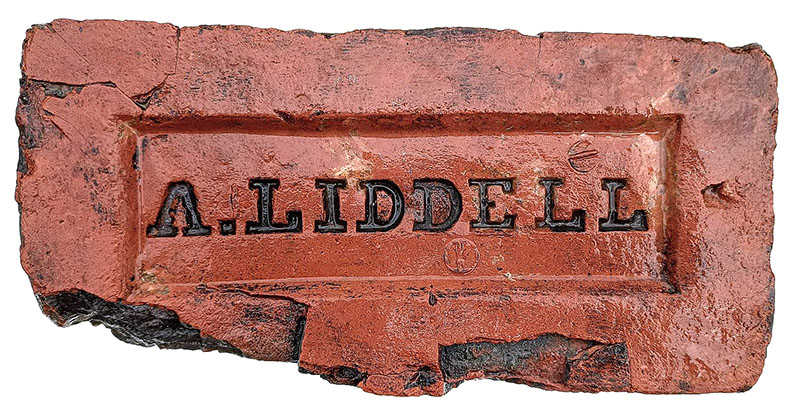

Reverse of the Lilco brick. S B = Snedshill Brickworks.

Lilco was a trade name of the Lilleshall Company and used for glazed and firebricks, photos by Frank Lawson.

Photo by John Harrison.

Photo by David Kitching

Photo by Vincent Charles Douglas.

Photo by Martyn Fretwell courtesy of the John

Baylis Collection.

The brickyard was established in about 1901, when Priestman Collieries Ltd took over the Lily Drift. Brick production reached a peak in 1955 at about 150,000 bricks per week, mostly for use at local pits. After 1964, high quality facing bricks were produced and were widely used in the North East, as for example at the Airport Hotel Ponteland and the Nuffield hospital, Jesmond. The brickworks closed in 1976. See also NCB Lilley. Photos and info by courtesy of the Frank Lawson collection.

Photo by David Kitching.

This Lily brick was photographed by Martin Briscoe in a display cabinet at Newhaven Fort, Sussex. It is possible that Lily were actually the makers of the brick machinery.

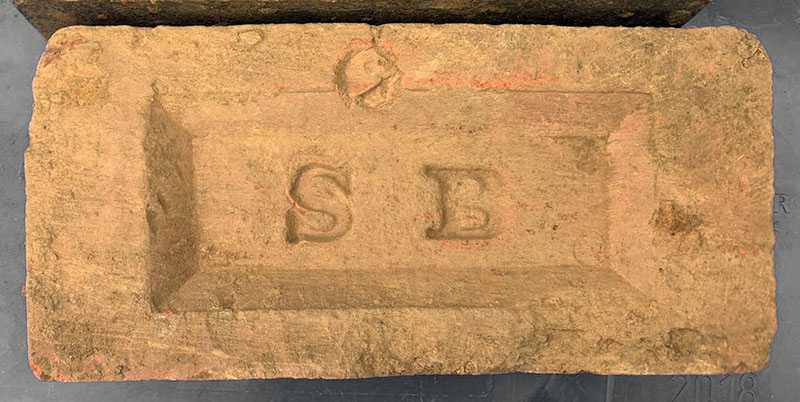

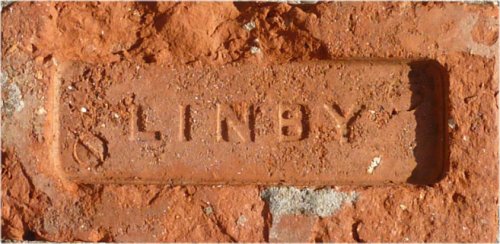

Linby Brickworks, Wighay Road, Linby, Notts. is shown as being on the edge of the village on the 1875 OS map. The works or it’s owners are not listed in any trade directories that from around 1875 & only the claypit is shown on the 1887 OS map. Today the houses built on Peverel Road occupy this site. Info & photographed at Papplewick Pumping Station near Nottingham by Martyn Fretwell.

Photo by Phil Jenkins.

A W: Albion works, Long Heys Road.

Photos by Frank Lawson.

Photo by Chris Tilney.

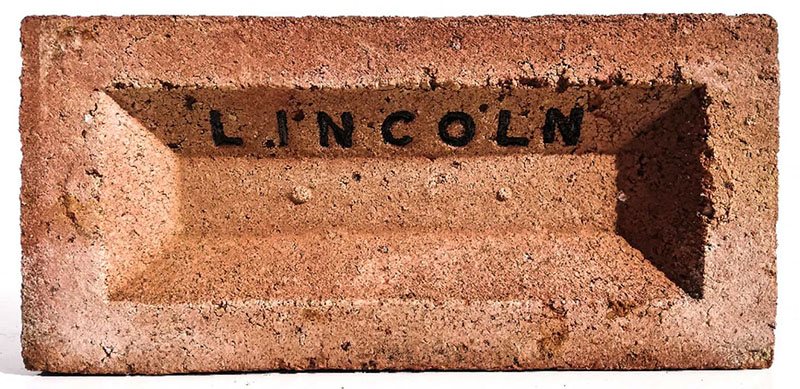

Photo by Sylvia Siddans.

B: Bracebridge works

W: Waddington works

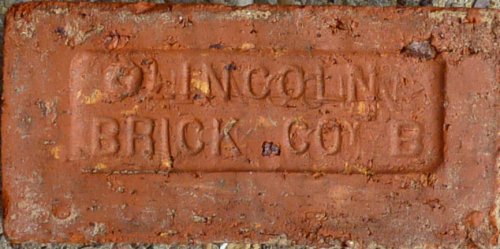

Lincoln Brick Co. operated five works during it's lifetime which

spanned from 1882 to 1975. These were at Waddington near Lincoln;

West Cliffe, Burton Road, Lincoln; Albion Works, Long Leys Road,

Lincoln; Cross O'Cliffe, Bracebridge & Brant Road,

Bracebridge. Photos & Info by Martyn Fretwell.

Photo by Jim Stevens.

Photo by Frank Lawson.

R Lineker, Balderton, Newark, Notts. Post Office Nottinghamshire Directory 1855. Info by Frank Lawson, photos by Ben Powell.

TIMOTHY & WILLIAM LINER are first mentioned in the 1847 POST OFFICE DIRECTORY for Northamptonshire, as brick makers. We then find that Timothy was born in 1804 & William in 1829, so presumably these were Father & Son. Timothy is then mentioned in Kellys directories for 1854, 1869 & 1877. By 1885 Kellys is listed as T. LINER (EXORS of) ROTHWELL & DESBOROUGH, sadly Timothy had passed away in 1880. Kellys 1890 lists Charles Liner, Desborough & Market Harborough. In 1898 & 1906 Kellys lists a Mrs. A. Liner, Desborough & Market Harborough AND William Liner, Rothwell. Then we find that for Kellys 1910 & 1914 William H. Liner, Rothwell. The works had certainly gone by the early 1920's. Photo and info by Nigel Furniss.

Made in Lingfield, Surrey. Photos by Richard Symonds.

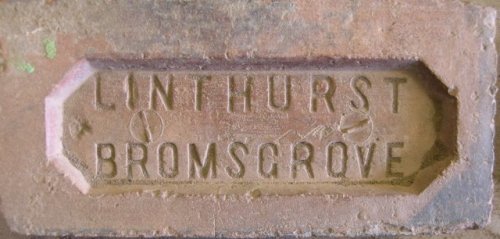

Simon Patterson photographed this one at Avoncroft Museum

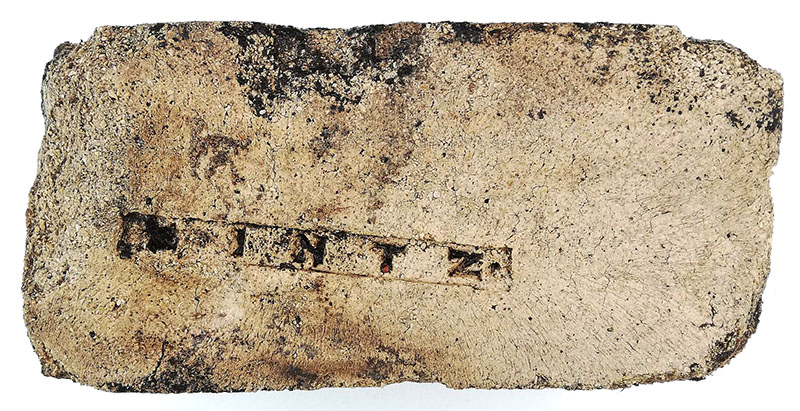

Lintz Colliery Company, Burnopfield, Co. Durham. One of Durham's

smaller colliery concerns, which via a series of owners operated in

various forms from the mid 1850's to around 1924. The associated

brickworks was an even shorter lived concern, being in production

for no more than 20 years from the late 1880's. However, despite the

relatively small size of the operation and its limited lifespan,

I've recorded at least three distinct renderings of the 'Lintz'

brand, with of course variations on the theme! Photo and info

by Arthur Brickman.

Photos by Chris Tilney.

Thanks to Darren Haywood for the photo.

Photo by Frank Lawson.

Photo by Mike Graham.

One of Tyneside's pioneering

brickmakers, reference to their first business venture is made

around 1827 with the establishment of a brickyard at Low Benwell on

the River Tyne, it's address being 'Benwell Fishery' and no doubt

the rationale for the adoption of the impressed 'Salmon' trade-mark,

which was carried on by their successors when their interests were

sold in the 1860's, by which time they had two yards at Scotswood

further west on the river; the Low Yard which employed some 50

hands, producing firebricks as in this example. Photo by Mark Cranston, added info by

Arthur Brickman.

Photo by Chris Tilney.

The brickworks and colliery were situated at Meadowfield, 2 miles SSW of Durham. Photo by Brian Yates.

The Winterton family acquired land at Bordesley Green, Birmingham

& established the Little Bromwich Brick Co. in 1899. The Little

Bromwich Brick Co. is listed in Kelly's 1899 edition with John Henry

Weston as managing partner. This entry is repeated up to the 1913

edition. Kelly's 1915 edition lists a second works at Black Pit

Lane, Ward End (now St. Margarets Avenue). The next trade directory

that I have for Birmingham is the 1940 edition and it still lists

the Little Bromwich Brick Co. at Bordesley Green. The company went

into liquidation and was voluntarily wound up on the 15th October

1951. Photo & Info by Martyn Fretwell.

Photos by Ray Martin.

The Littlewood works was situated close to Croston Station in West Lancashire. Photo by Jason Stott.

Livingston Refractories Ltd, Marshall Green Colliery, Witton-le-Wear, County Durham. In 1941 the business was working coal, ganister and clay at the colliery to produce refra tory bricks. The business seems to have been wound up in 1960.. Found a few miles south of Durham by Chris Tilney.

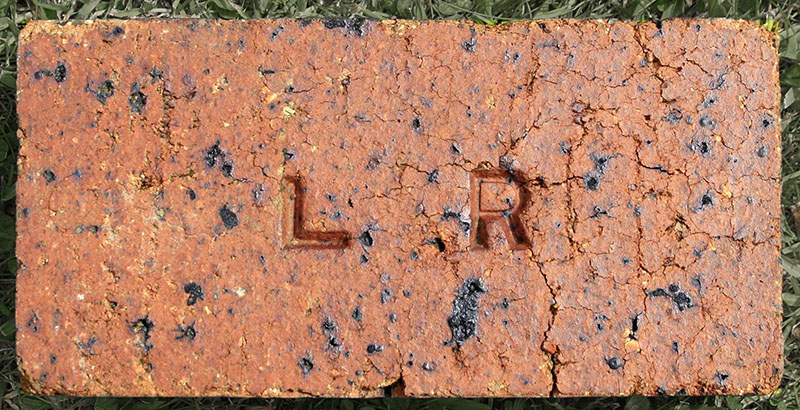

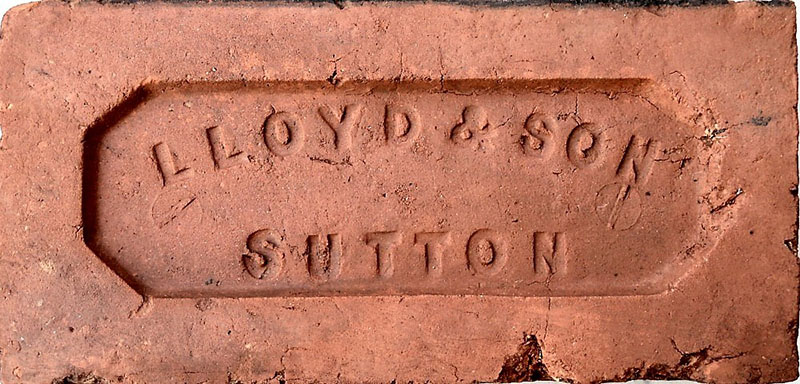

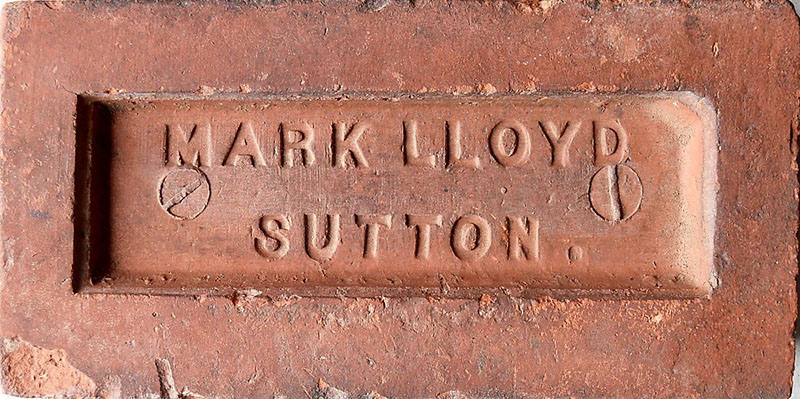

Lloyd & Son were first recorded as brick and tile makers in 1872, with similar records up to 1886. The next record from 1892 changes to Mark Lloyd, a son born about 1848, as the owner of the brickworks. Later records exist for 1916 and 1926-27, with the last record being in 1930. Kelly's directory for 1908 records Lloyds Brickworks Ltd as being located at the Sutton Old Yard and Wheatmoor brick works. An O.S. map of 1889 names an area between Bedford Road and Whitehouse Common Road as the Sutton Old Yard Brickworks. This includes three marl holes and four rectangles, three estimated about 40 - 50ft long, one 100 - 125ft long, marked as kilns. Other buildings and what could have been a wagon track for hauling tubs up from the quarry are also indicated. A later map of 1903 also names the Wheatmoor Brick and Tile Works, approximately half a mile away at Lindridge Road, that shows a clay pit, a building and four circles, probably beehive kilns. Bricks imprinted "Lloyd & Son" were used in the construction of the Sutton Park and Sutton Town stations on the Midland Railway line that opened in 1879.

This brick would have been produced after about 1890, after the death of Charles Lloyd, born about 1815, and his son Mark Lloyd became the owner of the brickworks. The 1891 census records that Dinah Lloyd was then a widow living with Mark and his wife. After brick making ceased about 1930, both pits were filled, the Old Yard area later used for housing and the Wheatmoor area reverting back to agricultural land. Photos and info by Ray Martin.

Quarry tile by Lloyd & Son. Photo by Jacqui Simkins.

Joseph Lobley was a Yorkshireman who was running his own brickworks at Bousfield, Stockton-on-Tees in 1881. By 1885 this business wasadvertising as the Imperial Brick and Tile Company (late J. Lobley). Joseph moved to W£alkden near Worsley in Lancashire where his wife's family lived. He worked at a brickworks there and eventually became manager by 1901. Photo by Mark Brown.

Locke of Hartwell near Aylesbury were in 1850 coal merchants and brick & tile makers. He had kilns at Hartwell, Stone & Doddershall. Three generations of Locke at Hartwell were producing bricks & tiles up to at least 1931. Photo and info by Nigel Furniss.

Reverse of brick. Clayton & Co Patent.

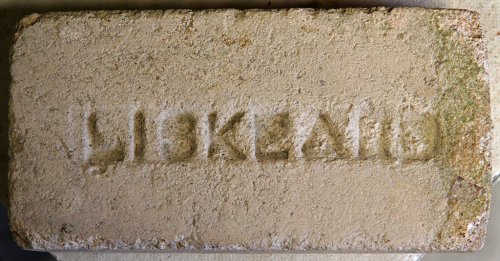

The Whitemoor brickworks had a complex history until 1872 when Walter Lockhart took it over and ran it until 1886 so the age of this brick is quite well defined. These were the first bricks to include the town's name. Thanks to Robin Leach for the photo and info.

Photo by Liz Robinson.

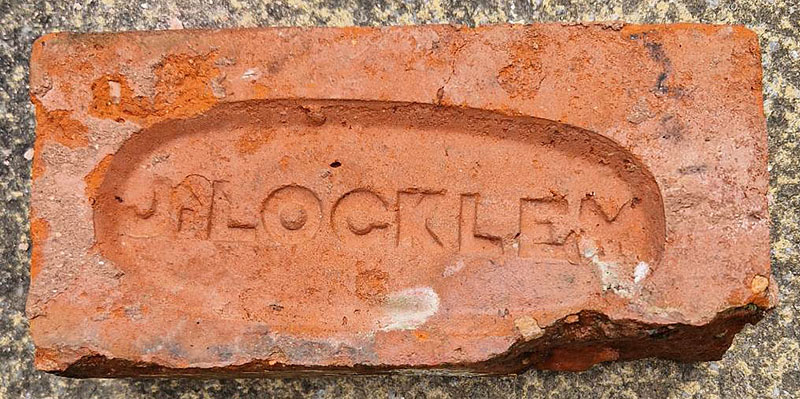

John Lockley is listed in the 1876 to 1884 Kelly's Directories at Green Lane, Merridale. Photos by Dave Hodgkinson.

Photo by courtesy of the Frank Lawson collection, found near Penistone. Philip Rothery writes that this a product of Lockwood & Elliott, Woodsome Sanitary Pipeworks, Fenay Bridge near Huddersfield.

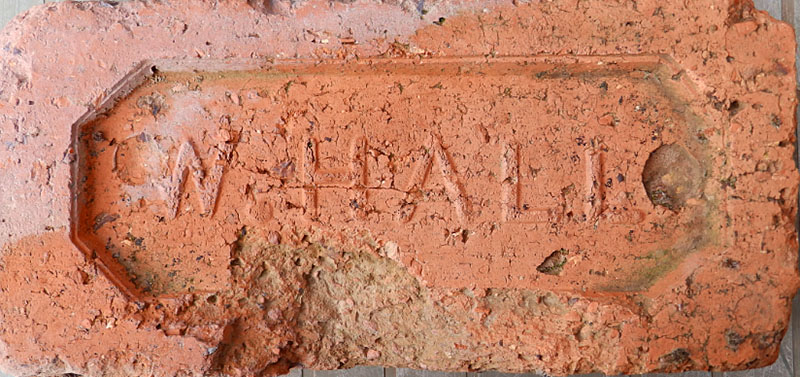

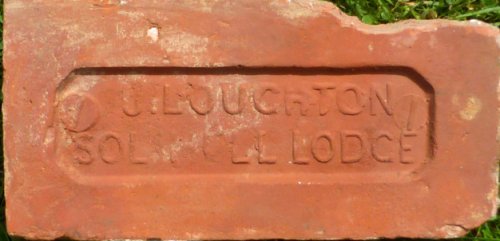

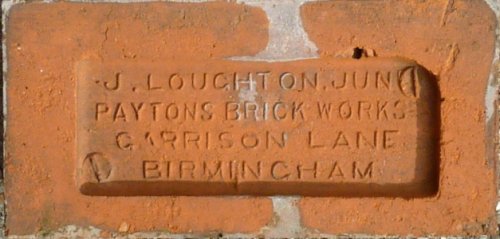

The

Lodge Colliery brickworks is first listed in Kelly's 1881

edition as William Hall, Lodge Colliery, Newthorpe. The entry in

Kelly's 1885 edition reads William Hall, Gilt Hill, Kimberley.

Kelly's 1888 & 91 editions is the same listing as the 1881

entry. White's 1894 listing is William Hall, Kimberley. Then the

last two listings are William Hall (exors. of), Lodge Colliery,

Newthorpe in Kelly's 1899 & 1900 editions. Lodge Colliery

together with it's brick kilns are shown on the 1879 map, so it

appears that the brick yard had just been established at this

date & it coincides with the first trade directory listing

for this yard in 1881. The 1913 map no longer shows neither the

colliery or brickworks & trees are shown planted on most of

this site. Today the Birch Industrial Estate has been

established next to the A610 on the part of the site where the

colliery & brickworks had stood. Photos by Ken Lord &

Info by Martyn Fretwell.

Photo by Nigel Furniss.

Photo by David Fox.

Photos by Frank Lawson.

Photo by Graham Shooter.

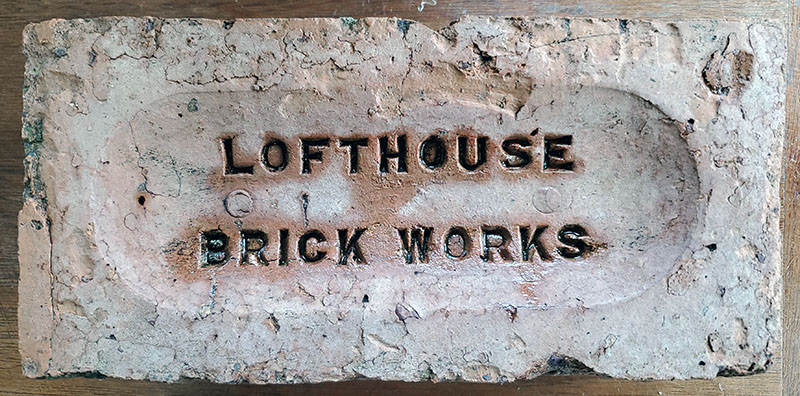

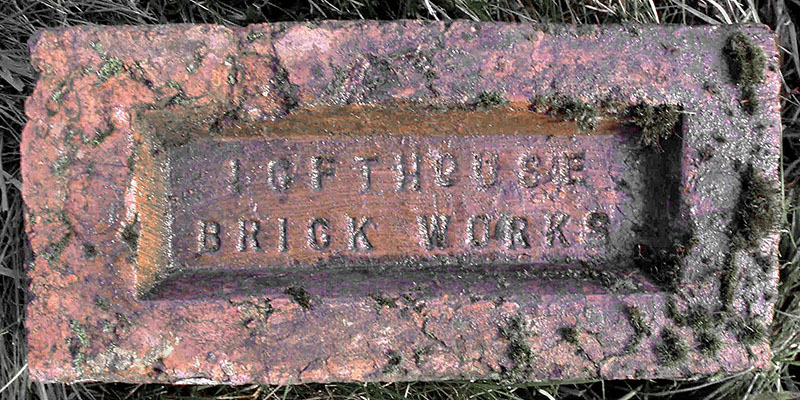

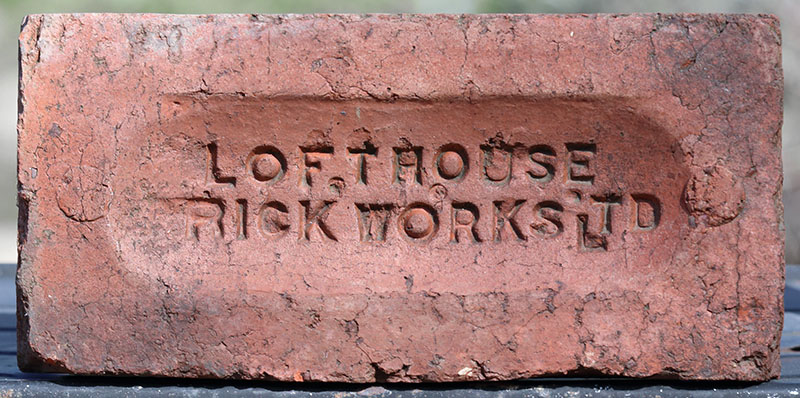

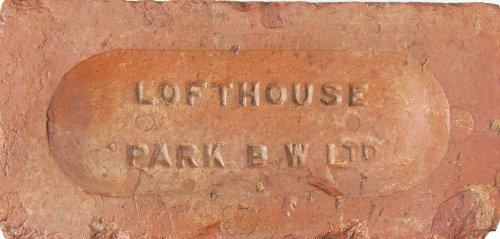

Lofthouse Park provided entertainment for the masses, 1908 - 1913. It was opened by the Yorkshire ( West Riding ) Electric Tramway Company and was situated at Lofthouse, 4.5km north of Wakefield, West Yorkshire. 'In the 1930s, Roper Brickworks moved into the Park across the road' Source: Peter I Wood, Lofthouse Park, in K. Taylor (edit) Aspects of Wakefield 1998. Image PRBCO.

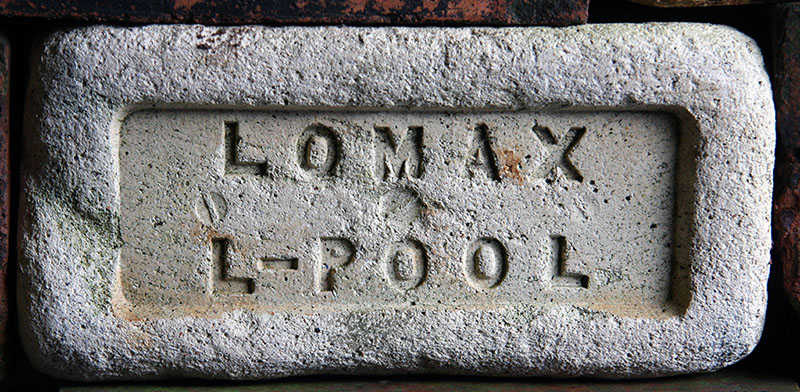

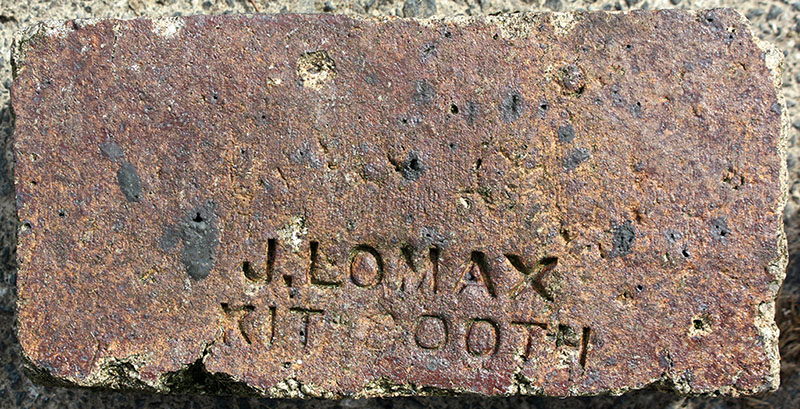

Kit Booth was a smallholding close to some of these and it is likely that this firebrick was produced at a kiln in the vicinity. In 1868-69 the works advertised in the Rochdale Observer.

Kit Booth Fire Brick and Tile Works, Spotland, Near Rochdale. Jeffrey Lomax (late Lomax and Lord), Manufacturer of Fire Bricks, Channel Bricks, Boiler Blocks, Flue Tiles, Flat Tiles and Bearers, Chimney Tops &c, &c, and Articles for Gas Works, &c. J.L. attends at the White Swan Inn, Rochdale, on Mondays and Wednesdays.

Photo by David Kitching.

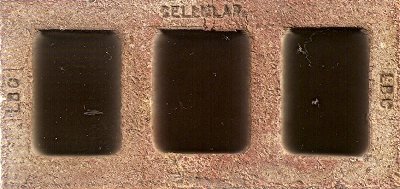

It has been estimated that a third of all the brick houses in England are built from London Brick Company bricks. The London Brick Company started production just over a century ago and usage peaked in the Post-War rebuilding period up to the Nineteen Sixties. Maximum production rose, at one point, to an amazing 16,000,000 bricks per day. In other words - quite common bricks!

there are a lot of photos of the London Brick Company on this Flickr site.

Photo by Phil Burgoyne.

Photo by John Reed.

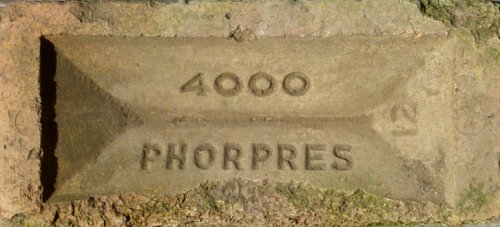

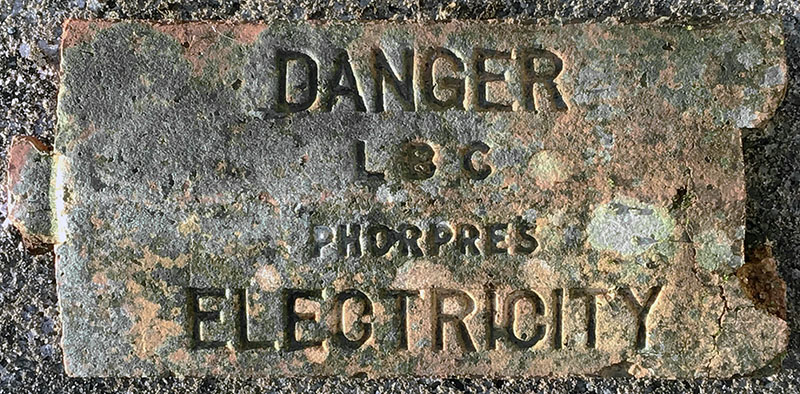

The early brick presses only applied two presses to the powdered clay in the brick moulds. The trade-name Phorpres came about because Fletton Bricks made in Bedfordshire are pressed twice in each direction so that they are literally 'four pressed' if the phrase is pronounced quickly it becomes Phorpres!

This one is a tiny sample brick. Photos by Frank Lawson.

Photo by Andrew Morley.

Photo by Mark Howard.

Photo by David Kitching.

Photo by Mark Howard.

Photo by Frank Lawson.

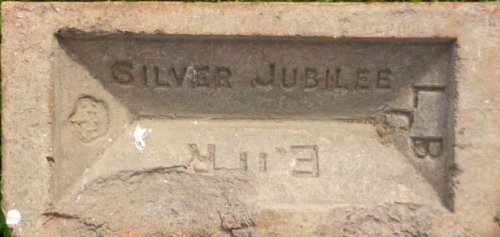

A commemorative brick by LBC, Thanks to Simon Patterson for the photo.

This photo of an LBC sample cellular brick was supplied by Michael Shaw. It measures 53 x 111 x 38mm.

This example was found in Edwardian alterations to an old house. Photo by Colin Midley.

Photo by Chris Tilney.

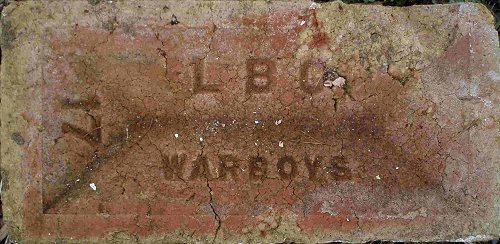

A Charles and Diana commemorative wedding brick, photo by Frank Lawson.

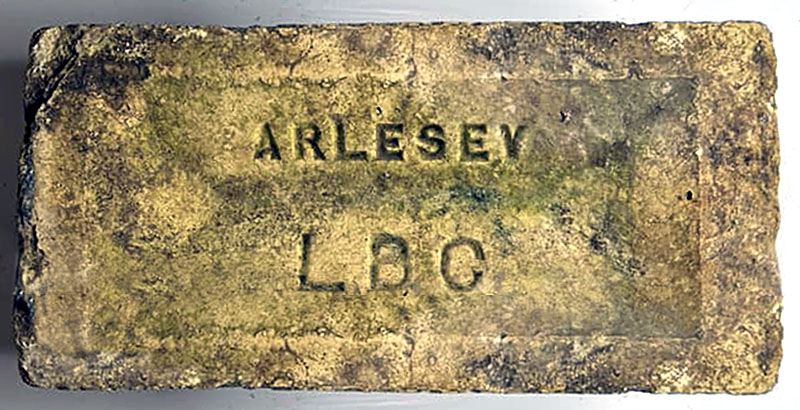

Photo by courtesy of the Frank Lawson collection, found near Woolsthorpe, Notts. Another of the Hanson casualties in 8/1984. Situated near Ramsey, Cambs and started 1886 by Alfred Fuller; Warboys Brick Works Co until 1933; LBC & Forders Ltd until 4/1936, then LBC. A 'Warboy's White' - they went over to land-drain pipes and hollow bricks 1950s. Now a tip. Additional info by Chris Fisher.

Photo by Frank Lawson.

41 is the code number allocated by the London Brick Company to its Northam works which it took over on 23 September 1924.Photo by Danny Rigby.

Found near Grimsthorpe Castle in Lincolnshire by Frank Lawson.

Photo by Frank Lawson.

Found at Snettisham, Norfolk. Probably made by LBC after they bought the Dogsthorpe Star brick works in the 1920s. Photo and info Chris Dixon.

Showing the 40th anniversary of the accession, 1952 - 1992. These came randomly in packs of L.B.C. facing bricks.

Photo by Alwyn Sparrow.

An old style LBC example, photo by Frank Lawson.

Photo by Martyn Fretwell.

These bricks were made as a low cost alternative for load

bearing party walls. Info & Photo courtesy of the Bill

Richardson collection at Southwick Hall by Martyn Fretwell.

Made at the former Farcet Brick Co.'s works, near Peterborough.

See Farco entry for info. Photo by Frank Lawson.

Photo by Michael Goddard.

Photo courtesy of the Bill Richardson collection at Southwick Hall

by Martyn Fretwell.

A tapered Phorpres marked 8ft diameter. Found at an old paper mill site in Barrow in Furness by Richard Comish.

Photo by Steve Reynolds.

Electricity tile. Photo by Peter Prest.

Does the 'L B' on this fairly modern brick refer to London Brick Company? Found in the Sheffield area by Andrew Richards.

The London and North Western Railway even made its own steel at Crewe, so brickmaking was almost a given. The 1876 1:2500 OS map shows a large round kiln near to West Street in Crewe along with rectangular kilns within the works buildings adjacnt to the Chester line. By 1898 the rectangular kilns had gone and the round kiln had a standard gauge siding entirely circling the structure. There were also four more smaller round kilns nearby. Info by David Kitching.

The L.N.W.R. was always willing to save money where possible and self sufficiency was the byword. In the mid 19th century bricks were often made on a building site, especially when large buildings were under construction. In a large enterprise like a railway new buildings were regularly required throughout the country, all needing large numbers of bricks. Large scale brick making began at Crewe in 1862 using clay from the cutting between the south end of Crewe station and Whitmore. The company had been paying 24 shillings per 1,000 for bricks from outside suppliers whereas company-made bricks cost just 16s.2d per 1,000. The bricks were handmade and so a lot of labour was involved.

In 1872 Chief Mechanical Engineer Francis Webb realised that the L.N.W.R. could make bricks more cheaply if the process was automated. At the time Crewe works were expanding and the clay spoil from the building site was dumped in a field where the clay sub-soil ran deep. Webb gave his Indoor Assistant and Assistant Steel Works Manager, John Aspinall, the task of building a 100ft diameter Hoffman kiln with a 114ft chimney. Two Pinfold brick making machines were driven by an old locomotive. Aspinall worked hard on the project and in the first eleven months about 4.8 million bricks were produced at the cost of 15 shillings per thousand. The brick making plant cost just £5,000 and gave a saving of 1s.2d per thousand, using mass production techniques. Aspinall described the final loading operation as follows:

Around the kiln is a line of rails, upon which the ordinary railway trucks run, and the finished bricks are loaded direct from the kiln into them, by two men who fill their barrows, wheel them to the trucks, and pile the bricks carefully inside, for 5.5 pence per thousand. One thousand bricks weigh three tons, and considering that this weight has to be moved twice and wheeled about fifteen yards, it is not a high rate.

Webb was so pleased with the success of the venture that he doubled Aspinall's salary.

Info from the Wolverhampton History & heritage Website.

Photo by Hamish Fenton

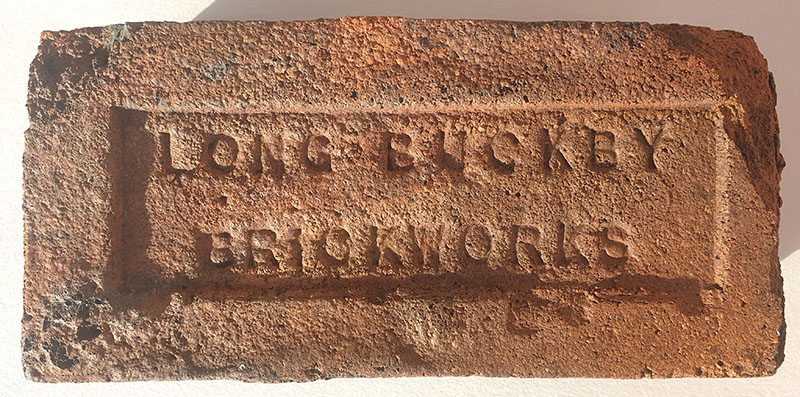

Found near Gayton on the disused S.M.J.R. line by Nigel

Furniss.

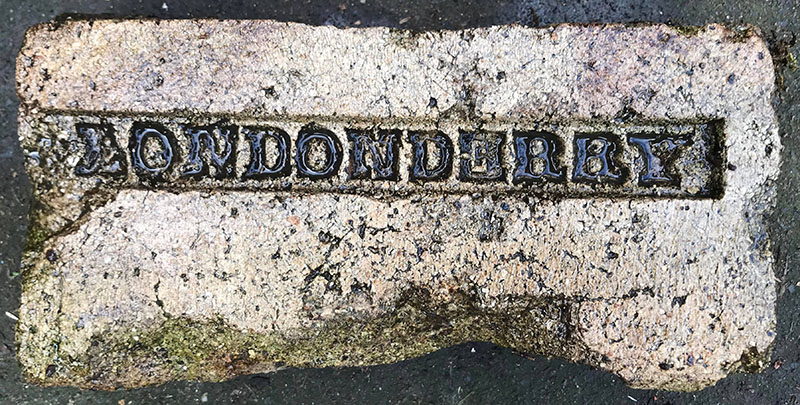

Photo by Chris Tilney. Londonderry

Collieries, County Durham.

Probably produced by The Londonderry Co. (part of the Marquess of Londonderry's Estates) at Seaham Colliery Brickworks, Co. Durham. Photo by Frank Lawson.

Photos by Steven Tait.

Photo by Liz Robinson.

This is an early lettered brick found in Leeds. The manufacturer might by Longley Bros of Hillidge Lane, Hunslet, or Thomas Longley & Sons, New Wortley who are both listed in White's directory for 1870 and 1872. Photo by Kevin Moyles

Possibly Joseph Longley, 1848 - 1857/8, whose yard was at Hunslet Road, Leeds. Found within the rear wall of the Clarence Iron & Steel Works by the Aire & Calder Navigation, Leeds. Image PRBCO.

The Longmead Brick Works was located in Bishopstoke Hampshire. Photo courtesy of Bishopstoke History Society.

Photos by Ray Martin.

Photo by David Kitching.

John Longson is listed in Slater's Stockport Directory for 1883 as a brick manufacturer at the Canal Wharf in Heaton Norris, Stockport. Found close to the Mersey in Stockport. Photo by Jeremy Nutter.

Longton Hall Co. Ltd.,(George A Mitcheson receiver & manager), Longton Hall Collieries, Longton & Fenton, Stoke. From Kelly's Staffordshire Directory 1896. Info by Frank Lawson.

Photos by David Kitching.

Photo by Frank Lawson.

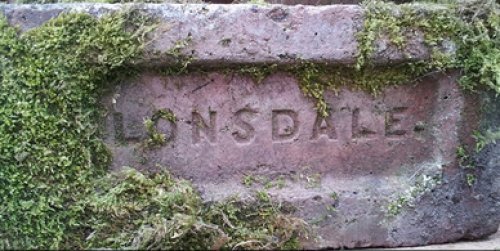

Lonsdale Brick and Tile Works, Cumwhinton, Carlisle.

The works was started by Claude Lonsdale as the Lonsdale brick and tile works. Kelly's Directory 1894 & 1897 lists Claud Lonsdale, Carlisle Tile and Pottery works. By 1911 the site was owned by M. Richardson and Son and from 1910 to 1938 it is listed as Lonsdale Brick and Tile works but the site was actually bought in 1930 by the Carlisle Plaster and Cement Company who also operated the nearby Cocklakes plaster works. Photo by Mark Cranston.

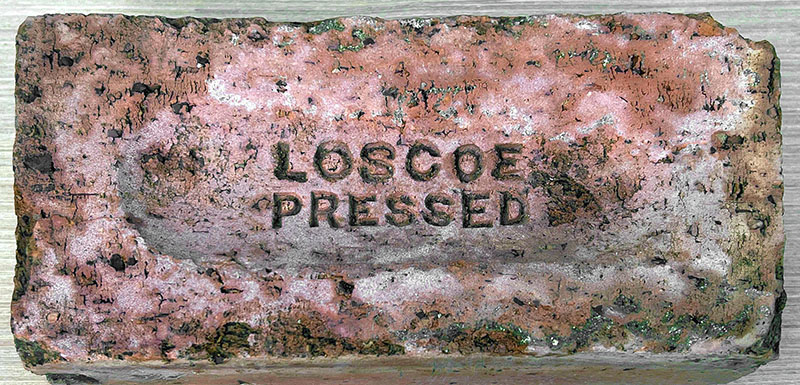

The Loscoe Brickworks was on Heanor Road, Loscoe, Derbys. and was in production from the 1880's to January 1976. When the clay pits were filled in & built over, a build up of methane gas from the material used to fill in the pits resulted in an explosion, destroying a bungalow. Fortunately without loss of life. Info & Photo by Martyn Fretwell.

Photo by Mick Farmer.

Joseph Love (1796-1875), son of William Love, a miner of New York, near South Shields, County Durham married in 1825 Sarah, daughter of Isaac Pearson, timber merchant, of North Shields, Northumberland. Joseph Love became a wealthy miller, shipowner, property developer and colliery owner, associated in particular with Chester-le-street, Shincliffe and Willington, County Durham and Durham City. He was a generous supporter of the Methodist New Connexion.

Joseph Love and Partners owned Shincliffe Colliery and Brick Works which was about a mile south of Durham. Joseph Love (1796-1875) was also a partner in Straker and Love (S&L), Ferens and Love (F&L), Love and Partner (L&P). Info by David Oliver, photo by Chris Tilney.

Joseph Horatio Love and Partners. J H Love was the grandson of Joseph Love and was born in 1853. Photo by Chris Tilney.

Photo by Phil Burgoyne.

Found in a structure on the Cassop Waggonway in County Durham. Photo by David Wigham.

Love & Partners, see above entry. Photo by Steven Tait

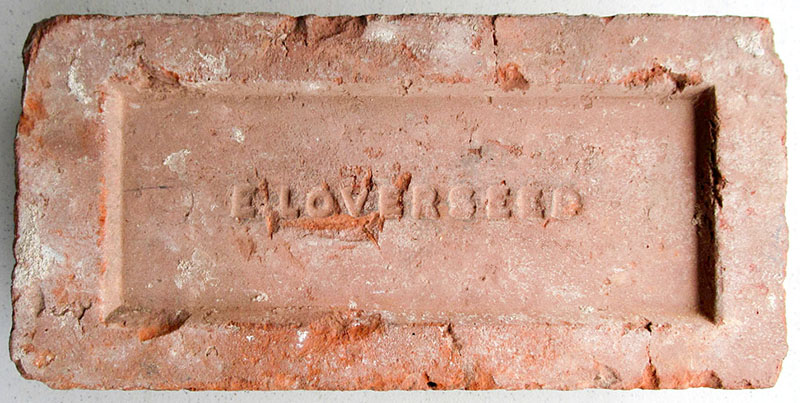

Edwin G. Loverseed is listed in Kelly’s 1864 edition at Mapperley, Nottingham & this brick is very lightly stamped with Mapperley on it’s reverse. White’s 1864 edition lists Loverseed at Woodborough Road, Mapperley & there were many small yards on this road around this date. Wright’s 1874 & Kelly’s 1876 editions then list Loverseed at 86, St. Ann's Well Road & this will have been his home address. By 1877 Loverseed was running the Nottingham Builders Brick Co. on Carlton Road, Sneinton Hill, Nottingham. Info & Photo by Martyn Fretwell, courtesy of Nottingham City Museums & Galleries.

Probably from the Low Moor Iron Company which operated collieries and ironworks a short distance from Bradford in West Yorkshire. Photo by Derek Barker.

Falkenhurst was a small area of Chadderton near Oldham and this brick was made in the vicinity in the early second half of the 19th century. I have so far been unable to identify anyone named Lowe as a brick manufacturer in the area or where exactly the brickworks was situated. Photos by Jason Stott.

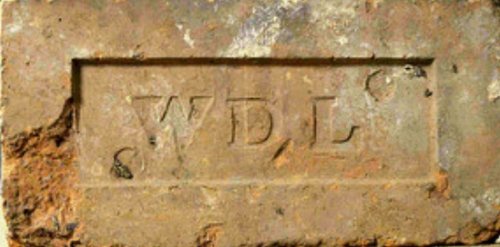

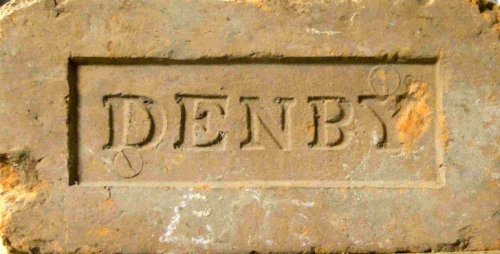

Ian Castledine writes: WDL stands for Wm Drury Lowe as in Drury Lowe

Colliery in Denby, Derbyshire, found at Flamstead drift.

Photo courtesy of Derby

Museums.

W D L represent the Initials of William Drury Lowe a local landowner

and industrialist. He owned several collieries in the Denby area in

addition to the brickworks. The brickworks was sold to W H & J

Slater in 1874.

William Drury Lowe of Locko Park, Spondon was able to extend the

lands and buildings he had inherited after he invested in the

creation of the Derby Canal. The canal made the collieries at Denby

much more viable as the coal could then be transported around the

country by canal, It is also assisted the creation of potteries at

Denby which started on Drury-Lowe's land. Photo by Phil Burgoyne, info by Frank Lawson.

John Grayson Lowood took over the former chemical works at Deepcar, establishing a ganister mine and refractory works, which produced a variety of bricks and other basic industrial requirements, the business was registered on the 1st of July 1890. White's Sheffield & Rotherham Directory 1919: - Lowood J Grayson & Co Limited, Wharncliffe Colliery & Silica Brick Works, Deepcar & 76 Attercliffe Road, Sheffield & at Middlesbrough. Photos by courtesy of the Frank Lawson collection.

Found near the former steel works in Workington. Photo by Chris Shaw.

Photo by Ian Suddaby.

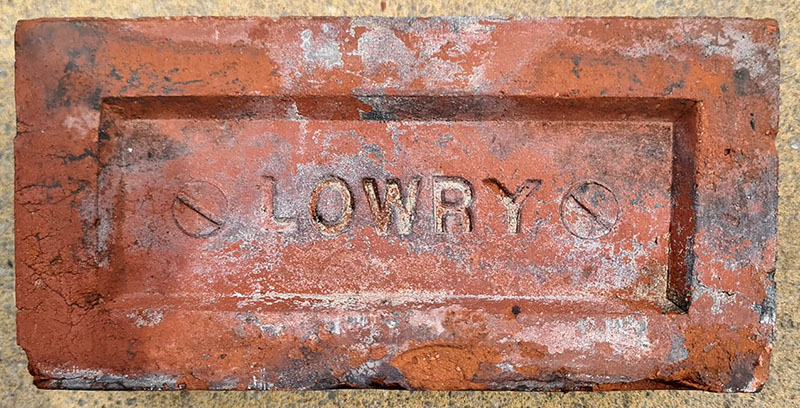

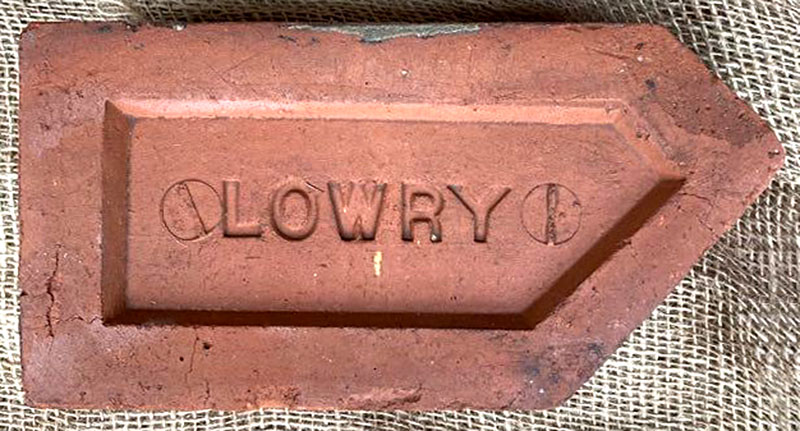

Made by the partnership of George Edward Lowry and Walter Lowry of Penshaw Quarries and Brickworks Ltd, County Durham. Photo by Anthony E Gray.

Photo by Ken Cunningham.

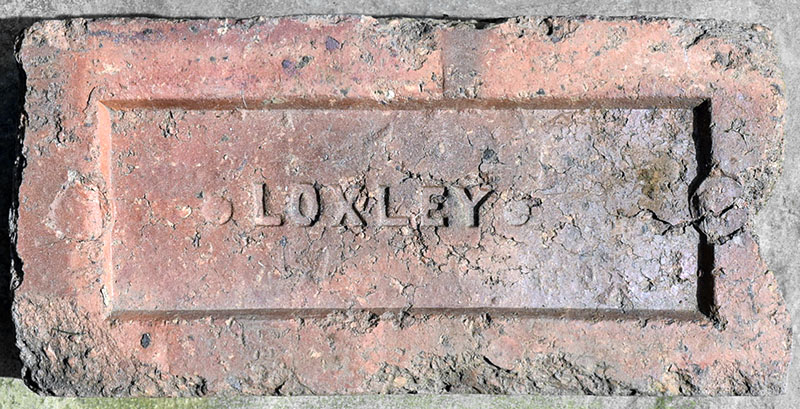

Thomas Marshall & William Crapper who owned the Storrs Bridge Brickworks in Loxley & records show

that they were at this works in 1864 when the Great Sheffield Flood took place. The duo are then

listed in White’s 1879 edition with the address of Loxley, Sheffield. At a date unknown Marshall &

Crapper went their different ways, Marshall stayed at the Storrs Brickworks concentrating on only

making refractory bricks & Crapper by 1893 Kelly’s Directory had moved to the Wisewood Brickworks just

down the Loxley Valley. Photo by

Simon Patterson & info by Martyn Fretwell.

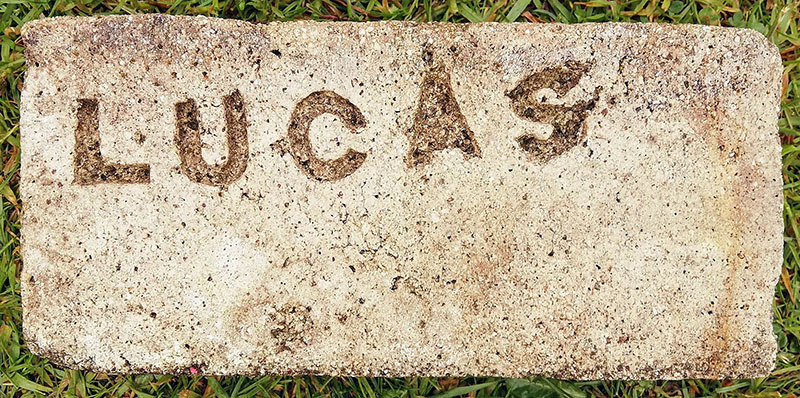

Abner Lucas was born in Tunstall, Staffordshire in 1798. In 1820 he was jailed for two years for his part in the assault of a member of the yeomanry in November of 1819. Soon after his release he seems to have moved to Tyneside where he established a firebrick works which in 1837 is listed at Ayton Banks nr Gateshead. By 1851 he was employing 26 men and by the 1860s was in partnership with his sons Peter Lucas, John Lucas and Robert Abner Lucas as firebrick manufacturers at Eighton Banks, Dunston, and Teams, all in the greater Gateshead area. He died in 1865 with his sons continuing the business. In April 1879 John Lucas and Robert Abner Lucas of Low Fell, Gateshead, fire-brick manufacturers became insolvent with liabilities of £8,500 and assets about £8,000. Photos by Chris Tilney.

Photo by Steven Tait.

Photo by Mark Howard.

Robert Lucock, brick and tile manufacturer at Langrigg, in the

parish of Bromfield, near Aspatria. Photo and info by Mark

Cranston.

Photos by Chris Graham.

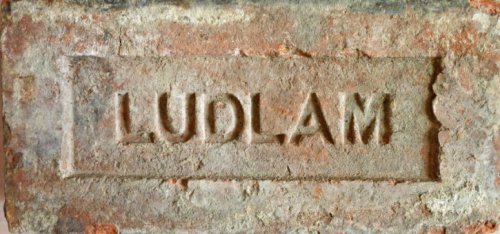

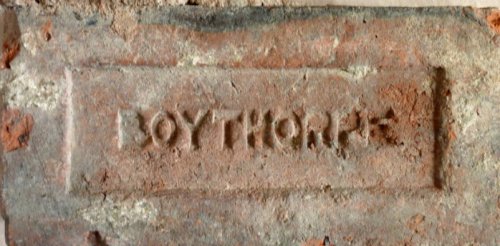

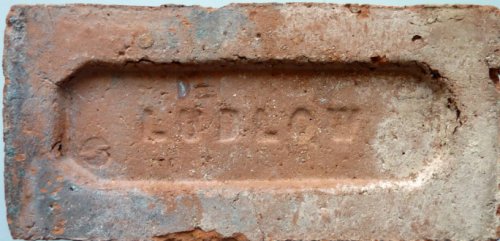

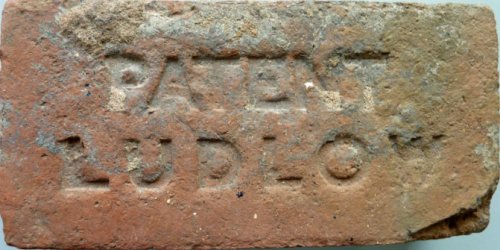

This brick was found in a wall at St Thomas's Hospital at Edgeley, Stockport which was built in 1841. The likely manufacturer for this is Thomas Ludlow whose works was at Heaviley in 1834. The Ludlow family went on to establish a brickworks on Turncroft Lane, Stockport. Various references list James Ludlow in 1876 & 85, Samuel Ludlow 1865 - 92, T & W Ludlow 1876. From the mid-1880s they are listed at Reddish, but that is many years after this brick was made. Photo by Lyn Bostock.

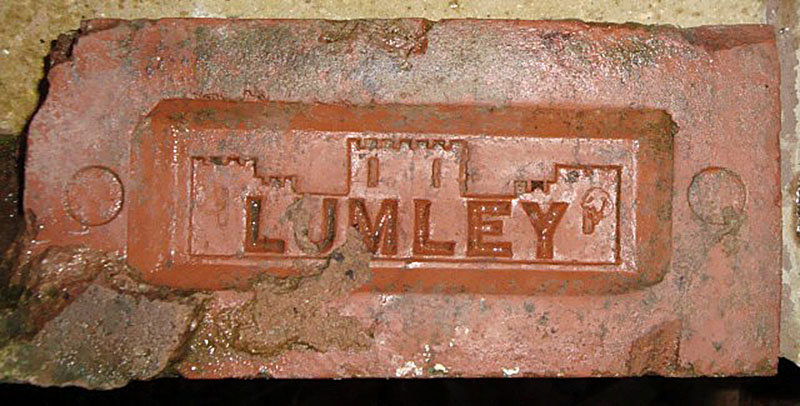

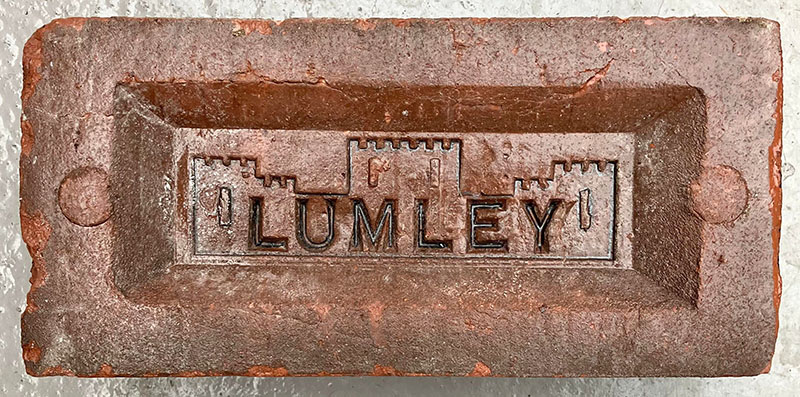

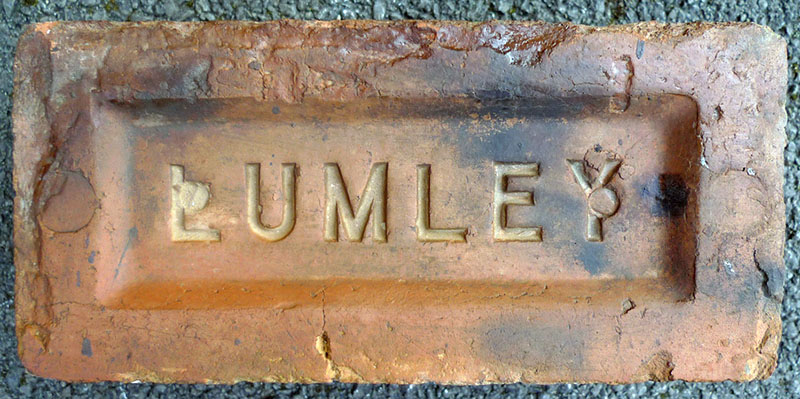

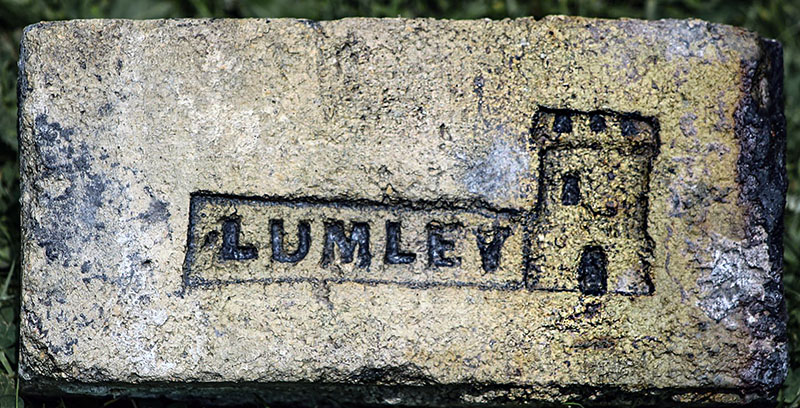

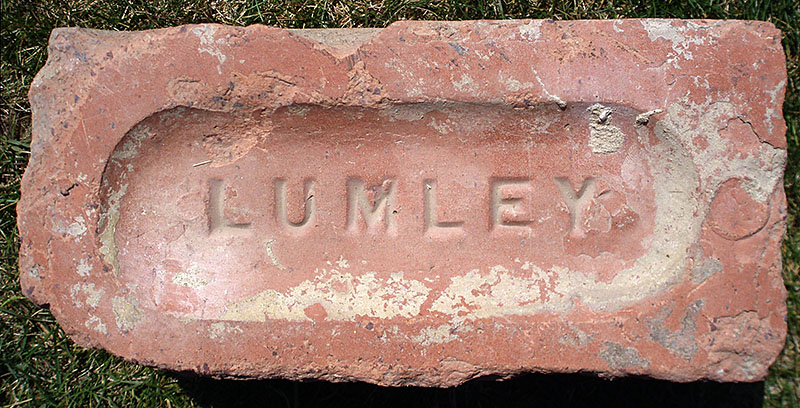

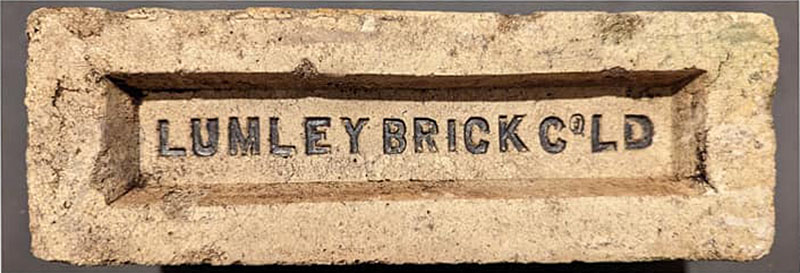

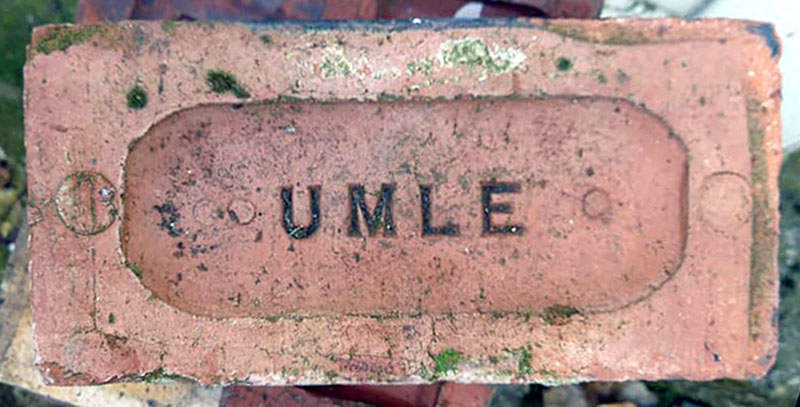

This one is from Chester-le-Street and features a representation of Lumley Castle, thanks to Simon Patterson for the photo.

Photo by Neville Akers.

Photo by Alan Davies.

Photos by Chris Tilney.

Photo by Frank Lawson.

Photos by Chris Tilney.

Photos by Frank Lawson.

Photo by Edith Stewart.

Photo by Frank Lawson.

Photo by Michael Hawkins.

Photo by Steven Tait.

Photo by Tony Gray.

Photo by David Kitching.

Photo by Kirsten Ellis.

Photo by Chris Tilney.

Photo by Steve Smith.

Photo by Phil Burgoyne.

Photo by Anthony E Gray.

Photo by Mike Graham.

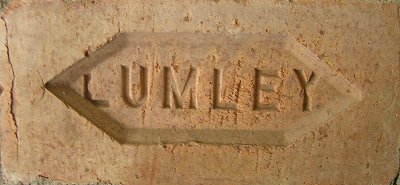

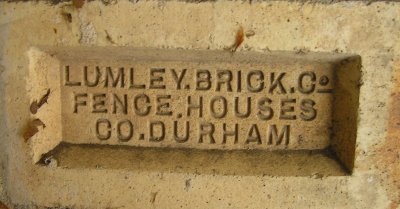

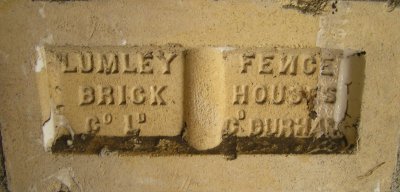

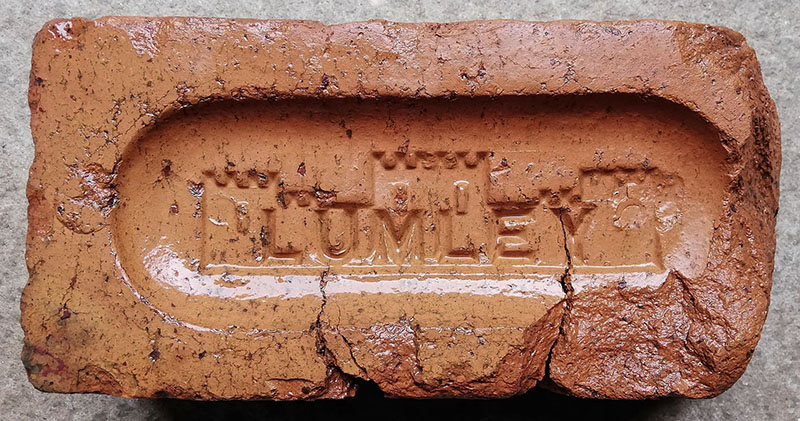

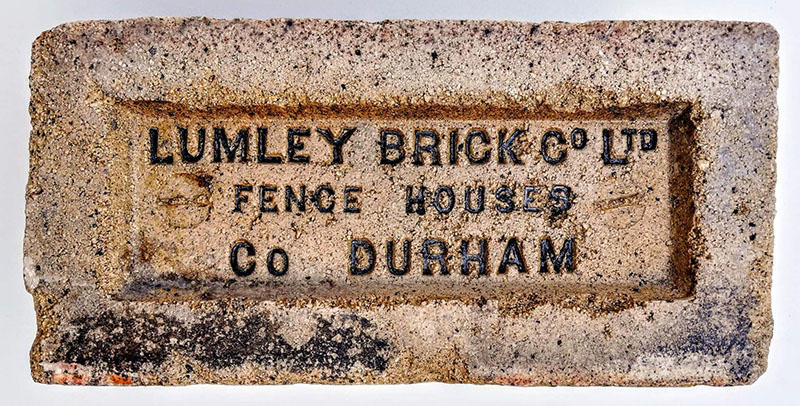

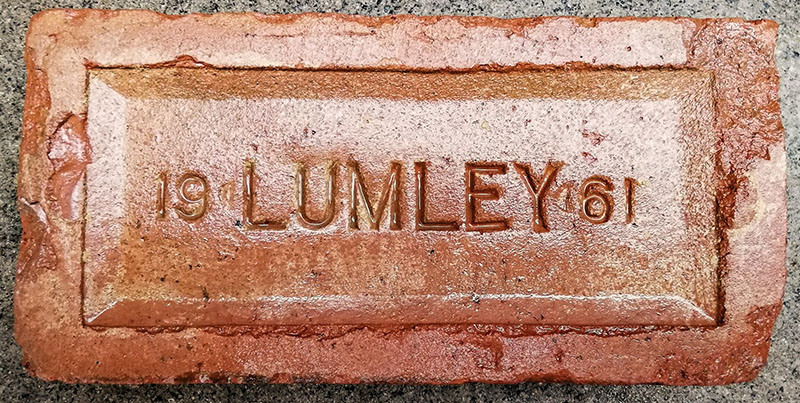

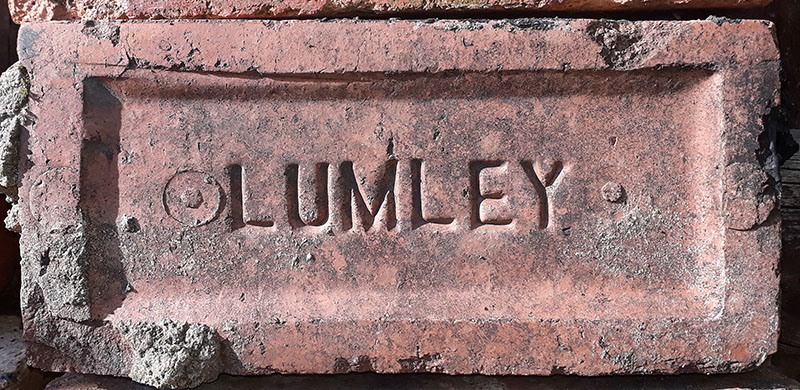

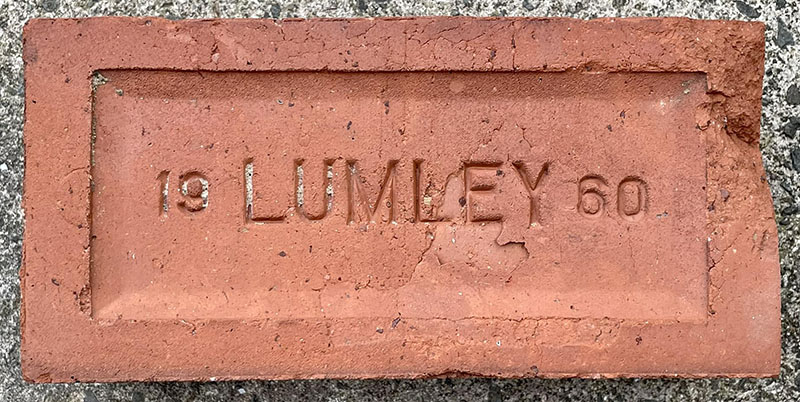

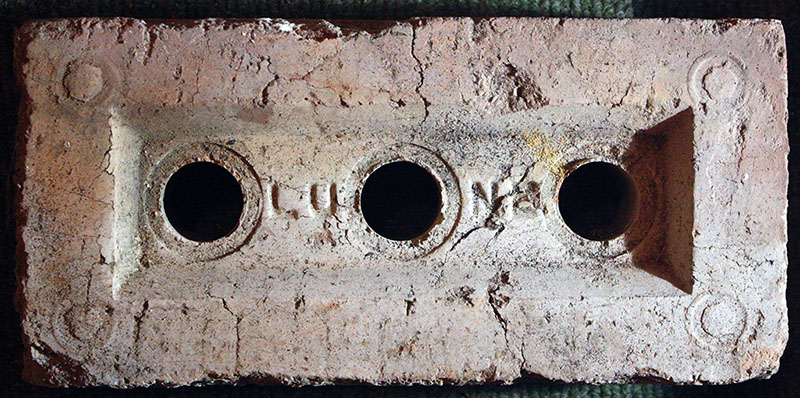

Lumley Brick Company was beside the Lumley 6th pit from 1870s to 1938. Early firebricks were marked Lumley with the outline of a fortified tower to represent Lumley Castle. Also produced enamel bricks glazed dark green, deep yellow, cream, and coffee brown. Clay came from the Low Main and 5/4 seams. Bricks were burnt in 6 circular downdraught kilns.

In 1937 Lumley Brickworks Ltd. re-opened an old brickworks and the fields next to it were opencast for shale. 2 Fawcett machine presses made engineering and facing bricks which were burned in 8 Newcastle kilns. In 1944 the Fawcett machines were prelaced by 2 Bradley and Craven presses. By 1950 there was 18 back to back Newcastle type kilns in 2 sets rows of 9. These were converted into a continuous kiln. an oil fired tunnel kiln was built in 1960. This was converted to gas in 1977 and the continuous kiln was disused. From 1980 bricks were made on a Spengler machine.

Information from Graham Brooks' website.

Found on Roeburndale Road, Caton Moor, Caton, near Lancaster by the site of the former Brookhouse Brickworks. LUNE, BROOKHOUSE and LUNE 1965 bricks can all be found close by the former brickworks and so it is quite possible that this was made at the Caton Moor site. 'Rural Industries of the Lune Valley, Winstanley 2000' states the works operated between the early 1920's and the late 1960's making quality bricks from the local shale. Image and info PRBCO. See also entry for Brookhouse.

Photo by David Kitching.

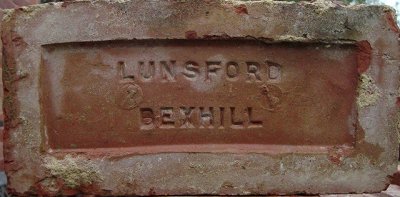

Found in Hastings by Simon Patterson, some info on the works here

The first reference found to the Lyttleton Brick Co. is a November 1930 job advert for Brick Setters for a top-fired continuous kiln, must be thoroughly experienced. Apply Lyttleton Brick Co. Albert Street, West Bromwich. The brickworks had been built on the site of the former Lyttleton Colliery which had certainly closed & the site cleared by the time of the 1900 OS map. A 1931 newspaper article reports bricks made by the Lyttleton Brick Co. were used to build Birmingham's Ice Rink. In March 1934 the newly formed Allied Brick & Tile Co. stated in their Share Prospectus that they had purchased nine brick companies & this included the Lyttleton Brick Co. which they had purchased from Alfred Edwin Thomas Hassall of 8, Beeches Road, West Bromwich for £31, 400. The 1943 Ministry of War Directory records Allied's Albert Street Works was closed & in the care of the Ministry and it is unlikely to have reopened. Photo by Bill Whitehead, info by Martyn Fretwell.

Photo by Phil Burgoyne.